The biotechnology industry is growing very fast. New ways to make vaccines, enzymes, and food appear every year. One key tool behind this progress is the stainless steel bioreactor. It is strong, safe, and easy to clean. It helps people grow cells and bacteria in a clean space. These machines make work faster and safer. They are used in labs, factories, and large plants.

They save energy and last a long time. They help companies work in clean and green ways. The new generation of stainless steel bioreactors is revolutionizing the way the world produces medicine and other biotech products. We are the best quality services provider and manufacturer.

The Evolution of the Stainless Steel Bioreactor

Many years ago, bioreactors were basic and slow. They could not control air, heat, or mixing very well. This made the results uneven and hard to repeat. Today, stainless steel bioreactors are much more advanced. They are made from strong steel that does not rust or break. They have sensors, screens, and intelligent control systems. These tools help keep the right air, food, and heat inside. Each part can be set to match the needs of the cells.

The interior is smooth and shiny, making it easy to clean and maintain. These bioreactors enable scientists and factories to consistently achieve clean, stable results. Our bioreactor is very strong and offers next-generation advanced solutions.

Key Features of Next-Generation Bioreactors

Modern stainless steel bioreactors are made for perfect control. They maintain air, water, and food in a clean and even state. One key part is magnetic mixing. This soft stirring method keeps everything smooth. It helps cells grow without damage. Old-style mixers with blades could hurt the cells. Magnetic mixing fixes that problem. Another feature is the PID control bioreactor system. It monitors temperature, air quality, and pH levels. It changes settings fast to keep everything steady. This means fewer mistakes and stronger results. The mix of gentle movement and intelligent control makes new bioreactors powerful and safe.

Why Stainless Steel Is Still the Best Material

Plastic bioreactors can be used only once, but stainless steel fermenters are stronger and more durable. They can handle heat and pressure without breaking. The smooth steel interior is easy to clean and does not retain germs. Many bioreactor manufacturers polish the metal so no dirt can stick. These machines can be used repeatedly. This makes them great for companies that make vaccines, food, or biofuels. They are used in both small labs and large factories because they consistently provide clean and steady results. Stainless steel remains the most trusted material for this work. We offer great and affordable wholesale prices.

From Lab to Pilot Scale: Growing Step by Step

All big processes start small. Scientists test their ideas in a laboratory bioreactor or lab stirrer fermenter first. These small machines help find the best conditions for growth. Once it works, they move to bigger systems like a pilot scale fermenter or a 100L fermenter. The design stays the same, only the size changes. This helps results remain the same when moving from the lab to the factory. The process becomes easy to repeat. Good fermenter manufacturers ensure that every model matches, making scale-up a smooth process. This saves time, reduces waste, and provides reliable production.

Magnetic Mixing Technology

A significant step forward is the magnetic mixing fermenter. This design uses magnets instead of blades or seals. It keeps the inside clean and closed. The magnetic mixing cell culture fermenter moves quietly and softly. It stirs the culture without hurting it. The smooth motion helps cells grow fast and stay healthy. It also stops leaks and reduces maintenance. This saves money and time. Many bioreactor manufacturers now use magnetic mixing in both small and large systems. From lab units to factory tanks, this innovative mixing method ensures that production remains safe and efficient.

PID Control System for Precision

Reasonable control makes good results. A PID control bioreactor utilizes sensors to continuously monitor temperature, air, and pH levels. If something changes, it fixes it right away. This keeps everything in balance. It helps cells grow in perfect conditions. It is instrumental in producing vaccines and enzymes that require stable environments. It also saves people time and lowers human error. As a result, most new stainless steel bioreactors utilize PID control systems. They keep the process simple, smart, and always under control. This enables companies to consistently produce better products.

Wide Uses in Many Industries

The stainless steel bioreactor is used in many industries. In medicine, it helps make vaccines and proteins. In food, it is used to make yogurt, cheese, and drinks. In energy, it helps make biofuels. In farming, it makes enzymes and acids. Some types, like the solid state fermenter and anaerobic bioreactor, work with special microorganisms that grow without air. These systems can handle many jobs. They are used in labs and big factories alike. They make production cleaner, faster, and easier. Around the world, companies rely on these machines to make better products.

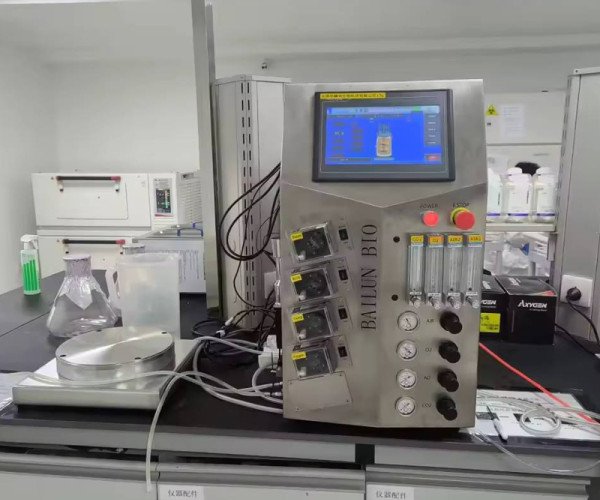

BLBIO-GCUC Magnetic Mixing Cell Culture Fermenter Bioreactor Process Model Manufacturers

The BLBIO-GCUC Magnetic Mixing Cell Culture Bioreactor Fermenter is an excellent example of a new design. It is made of strong stainless steel that is easy to clean. It utilizes magnetic mixing, which ensures the safety and uniformity of the culture. There are no seals, so there are no leaks. It features a PID control system that maintains steady air, pH, and temperature levels. It can grow both bacteria and animal cells. It is simple to use and easy to care for. For any bioreactor manufacturer, this model shows the future of bioprocessing. It is bright, strong, and saves time and energy.

Laboratory Bioreactor Microbial Vaccine Stainless Steel Reactor Lab Stirrer 100L Fermenter

The Laboratory Bioreactor Microbial Vaccine Stainless Steel Reactor Lab Stirrer 100L Fermenter is made for small labs and pilot plants. This 100L fermenter is excellent for making microbial vaccines and other products. It mixes smoothly and keeps a steady temperature. The lab stirrer fermenter design enables scientists to obtain good results quickly. It is built to last and simple to clean. The steel body stops rust and keeps everything safe. Many fermenter manufacturers trust this model because it is flexible and dependable. It helps labs prepare for larger production while maintaining high quality.

Stainless Steel Material Solid Fermenter Tissue Culture Equipment Anaerbico Bioreactor

The Stainless Steel Material Solid Fermenter Tissue Culture Equipment Anaerbico Bioreactor is made for special processes. It is used for solid state fermentation and anaerobic bioreactor work. It grows microorganisms that live in the absence of air. The stainless steel body is strong and sealed tightly. It carefully controls air, temperature, and moisture. This creates the ideal environment for producing enzymes, organic acids, and biofuels. It can be used for both research and production. This bioreactor demonstrates how innovative design and robust materials make even complex tasks safe and easy.

Sustainability and Efficiency

Green work is essential today. Stainless steel bioreactors help protect the planet. They can be cleaned and reused, resulting in less waste. Cleaning them is quick and easy with CIP and SIP systems. They use less power because they hold steady heat. This saves money and energy. These bioreactors last for years, so companies do not need to buy new ones often. They help people work cleanly and save the environment. Stainless steel bioreactors demonstrate that good technology can also be environmentally friendly and respectful of nature.

The Future of Bioprocess Engineering

The future of bioprocessing is full of new ideas. Soon, stainless steel bioreactors will get even smarter. They will utilize sensors and AI to monitor the entire process. They will adjust settings on their own. They will need less help from people and make fewer mistakes. For bioreactor manufacturers, the goal is to build systems that are flexible and clean. For users, that means better results and lower costs. As technology advances, stainless steel bioreactors will continue to lead the way to safer, smarter, and greener production.

Reliable Stainless Steel Bioreactors for Labs and Industry

Enhance your biotech work with Bailun Biotech (Jiangsu) Co., Ltd. Our stainless steel bioreactors are very safe and user-friendly. They allow you to grow cells, bacteria, and vaccines with consistent results every time. You can choose a small laboratory bioreactor, a 100L fermenter, or a larger pilot scale fermenter. Each system is designed to function efficiently and last for an extended period of time. With magnetic mixing, PID control, and durable stainless steel, production is reliable and straightforward. Trust Bailun Biotech, your expert bioreactor manufacturer. Contact us today to improve your lab and factory work.

The stainless steel bioreactor is strong, safe, and easy to use. It helps grow cells and produce products, from small labs to large factories. With magnetic mixing and PID control, it operates efficiently, conserves energy, and minimizes waste.

FAQs

- What is a bioreactor made of stainless steel?

A bioreactor made of stainless steel is a robust, safe tank used to cultivate cells, bacteria, and other microorganisms. It works in labs and factories and is easy to clean.

- Why should you use a bioreactor made of stainless steel?

It lasts a long time, can be used repeatedly, and keeps things clean. It works well for both small and large production runs, providing consistent results.

- What does it mean to mix things with magnets in a bioreactor?

Magnetic mixing gently stirs the culture, preventing cell damage. It helps nutrients and air mix together well.

- In a bioreactor, what does PID control do?

PID control continuously monitors temperature, pH, and oxygen levels and adjusts them accordingly. This ensures that growth remains steady and reliable.

- What are the different sizes of bioreactors?

There are small lab bioreactors, 100L fermenters, and larger pilot-scale systems used in factories.

- What can be made in a bioreactor made of stainless steel?

They can make biofuels, probiotics, enzymes, vaccines, and other biotech products.